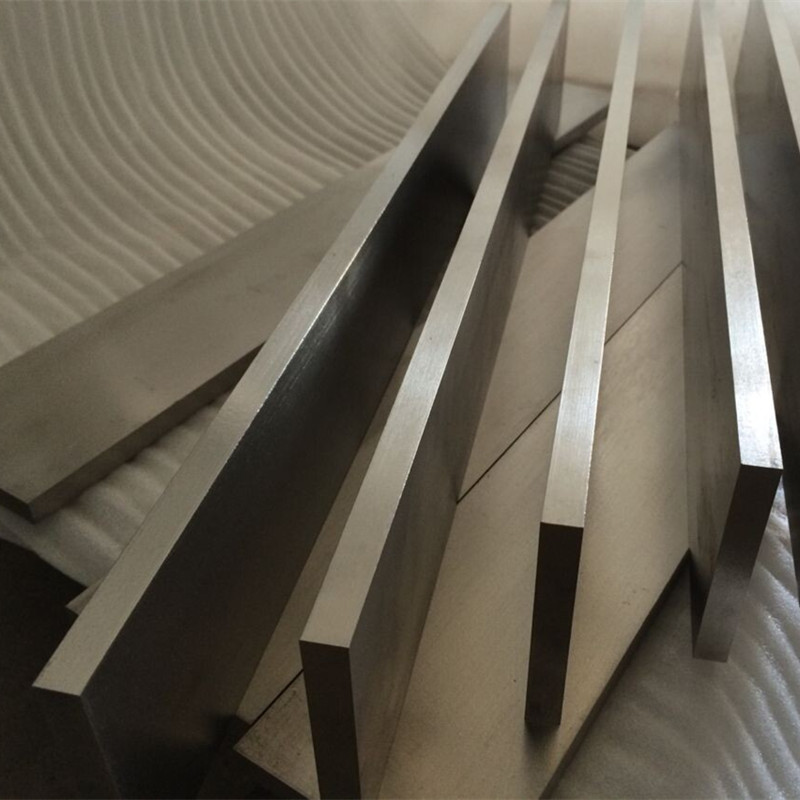

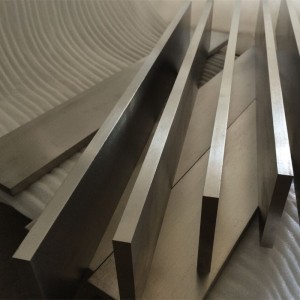

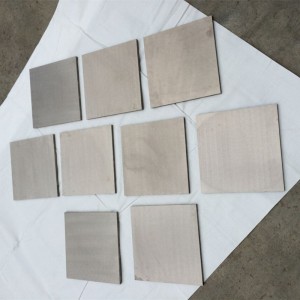

Duilleag Alloy Titanium Plate Titanium Pure

Tuairisgeul

Sònrachaidhean duilleag Titanium Pure / Titanium Alloy:

Stuth Ìre: Gr1, Gr2, Gr3, Gr4, Gr5, Gr7, Gr6, Gr9, Gr11, Gr12, Gr16, Gr17, Gr25, TA0,TA1,TA2,TA5,TA6,TA7,TA9,TA10,TB2,TC1,TC2 ,TC3,TC4

Coitcheann ASTM B265, ASME SB265, DIN17851, TiA16Zr5Mo1.5, JIS4100-2007, GB3461-2007

Meud:

Rolladh fuar: Tiugh 0.02mm ~ 5mm * leud 1500mm max * Fada 2500mm max

Rolladh teth: Tiugh 5mm ~ 100mm * Leud 3000mm max * Fada 6000mm max

Iarrtas Plate Alloy Titanium

1. Stèidhichte air Àrd dian, titanium bathar tensile neart urrainn a bhith suas ri 180Kg/mm².

2. Titanium agus titanium alloy ann an gnìomhachas adhair, canar "space metal"; A bharrachd air an sin, ann an gnìomhachas togail shoithichean, tha cleachdadh a’ sìor fhàs farsaing aig gnìomhachas ceimigeach, saothrachadh pàirtean innealan, uidheamachd cian-conaltraidh, alloy cruaidh, msaa.

3. A bharrachd air an sin, air sgàth an titanium alloy leis a ’chorp daonna tha co-chòrdalachd fìor mhath aige, agus mar sin faodaidh an alloy titanium a bhith na chnàmh fuadain cuideachd.

Is e titanium 6AL-4V Gr5 ris an canar cuideachd Ti6Al4V, Ti-6Al-4V, Ti6-4 no Titanium 6Al-4V Alloy, an alloy as cumanta a chleachdar. Tha e gu math nas làidire na titanium fìor-ghlan gu malairteach fhad ‘s a tha na h-aon stiffness agus feartan teirmeach aige. Tha duilleag & truinnsear titanium AMS 4911 6AL-4V na dheagh thaghadh de dhuilleag titanium itealain ann an grunn shònrachaidhean.

Feart de dhuilleag & clàr titanium AMS 4911 6AL-4V

● Dùmhlachd Ìosal agus Neart Sònrachaidh Àrd.

● Math an aghaidh buaidh teas.

● Modulus ìseal de elasticity.

● Feartan teirmeach math.

Dèanamh ceimigeach de Titanium agus Titanium Alloy

| Ìre | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

Neart tensile Titanium agus Titanium Alloy

| Ìre | Leudachadh (%) | Neart tensile (Mion) | Neart toraidh (Mion) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |